The Cotton Club develops the Private Label area.

The first private label manufacturing contract was concluded more than 12 years ago, with METRO C&C network being the first customer. To date, Cotton Club continues to actively develop the Private Label area.

More than 70 large retail and pharmacy chains entrust us with the manufacture of their trademarks.

In 2011, within the framework of the Private Label Awards Russia, Cotton Club won Private Label Company of the Year award in the manufacture of cotton and hygiene products.

In April 2017, following the results of the 2nd annual Private Label Awards (by IPLS), the Cotton Club Group was named the best Private Label Producer among non-food items.

Products manufactured by the company under contracts:

- Cotton pads

- Cotton buds in polyethylene, glass, square cotton buds, baby cotton buds.

- Wet wipes (baby, refreshing, intimate, antibacterial, make-up removing, household, etc.) and wet toilet wipes

- Disposable nappies

- Liquid detergents (liquid soap, intimate hygiene products, shower gels, shampoos), as well as children’s gels, creams, lotions, milk and scrubs.

- Disposable diapers and panties

Cotton pads

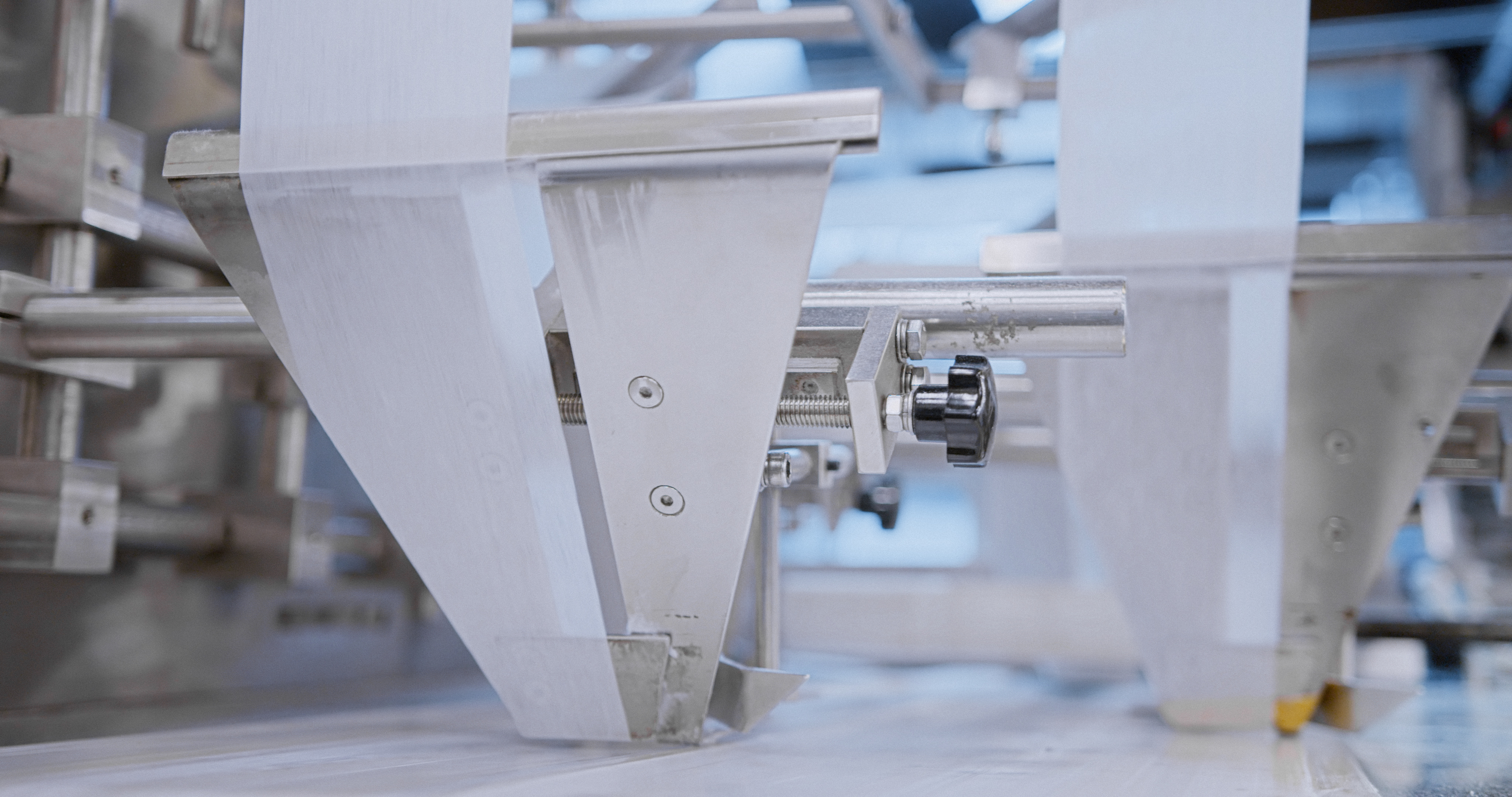

The latest Water Jet technology is used for the production of cotton pads, thanks to which they have a smoother surface, they don’t exfoliate and don’t shed.

Cotton pads can be produced with various types of embossing, and the edge of the pad can be with or without stitched effect.

Product Specification:

Material: 100% cotton

Types of pads: round, oval, rectangular

Types of pads: round, oval, rectangular

Density of a pad: 160 g/m², 170 g/m², 190 g/m², 220 g/m²

Packing type:

- plastic bag with rope

- plastic bag with Eurohold

Type of packing material: polyethylene

Packaging technology: automatic

Shelf life: unlimited

Cotton buds in polyethylene, glass, square cotton buds, baby cotton buds.

High-quality polypropylene and natural cotton fiber are used for the production of cotton buds.

Product Specification:

Types of packaging:

- polyethylene bag (100, 160, 200, 300, 400 pcs.)

- square glass with or without easy click (200, 300 pcs.)

- round glass (100, 200 pcs.)

- monoblock (300 pcs.)

Types of packaging material:

- polyethylene (bag)

- polypropylene (glass, monoblock)

Stick composition: polypropylene

Color of polypropylene stick: custom

Stick weight: 0.165 ± 0.005 g

Stick length: 72.0 ± 0.5 mm

Weight of a cotton bud:

- standard / cosmetic: 0.23 ± 0.1 g

- safety bud: 0.4 ± 0.2 g

Packaging technology: automatic

Shelf life: unlimited

Types of products:

- classic cotton bud

- baby safety cotton bud

- cosmetic cotton bud

Wet wipes

All wet wipe production lines are high-tech and fully automated, there is an applicator for applying the lid.

When impregnating wipes, the own-produced lotions are used.

Categories of wet wipes:

- Baby wipes

- Refreshing wipes

- Wipes with antibacterial effect,

- Antibacterial

- Make-up removing wipes

- Intimate wipes

- Cleaning wipes

- Car wipes

- Wet toilet wipes

Product Specification:

Type of wipe material: spunlace (bamboo, viscose fiber, polyester fiber, and also a mixture of these fibers)

Dimensions of wipes:

- standard with cross-fold – 110*170mm, 125*185mm, 150*185mm, 170*185mm

- standard with interfold – 200*160mm, 175*180mm, 170*130mm.

Other options for the size of wipes are available as may be agreed upon with the customer

Surface density of the fabric: 35-55 g/m2

Structure of the fabric material: smooth, textured, perforated.

Packing options: three-seam package, with one longitudinal and two transverse seams:

- Pocket packaging with a sticker (Pocket);

- Big package with a sticker or cover (Big-pack)

Type of packaging material: polyethylene + PET (lavsan)

Number of wipes in the package: from 8 to 120 pcs;

Packaging technology: automatic

Shelf life: 2 years

Specification of wet toilet wipes:

Wipe material type: spunlace, airlade.

Wipe dimensions: with interfold - 190 * 120mm, 125 * 185mm.

Other options for the size of wipes are available as may be agreed upon with the customer

Surface density of the fabric: spunlace 35-50 g/m2, airlade 50 g/m2

Packing options: three-seam package, with one longitudinal and two transverse seams:

- Pocket package with a sticker (Pocket);

- Big package with a sticker

- or a lid (Big-pack)

Type of packaging material: polyethylene + PET (lavsan)

Number of wipes in a package: 20, 72

Other quantities of wipes are available as may be agreed upon with the customer.

Packaging technology: automatic

Shelf life: 2 years

Disposable nappies

Disposable nappy is a multilayered product:

1. Bottom layer - non-slip polyethylene (of different colors, with or without print);

2. Medium absorbent layer - 100% dissolved cellulose;

3. Top layer - soft non-woven material - hydrophilic spunbond (white/colored)

Manufacture of disposable diapers of various sizes: 60 * 40 cm, 60 * 60 cm, 60 * 90 cm. Special production technology allows to evenly distribute the cellulose (absorbent) layer throughout the area of the diaper, which significantly enhances the quality of the product.

Types of disposable nappies:

- For babies;

- For adults;

- For animals;

- Flavored.

Product Specification:

Material:

- non-slip polyethylene (bottom layer);

- 100% dissolved cellulose (medium absorbent layer);

- soft spunbond non-woven material - hydrophilic spunbond (top layer)

- hot melt glue

Packing: with handle / without handle

Packing material: plastic bag

Quantity in a package: 3, 5, 10, 20, 30 pcs.

Packing method: automated

Shelf life: 5 years

Liquid detergents

Own shop for the production of liquid detergents and cosmetic products makes it possible to produce the following range of products:

- Liquid soap

- Intimate hygiene products

- Shower gels

- Liquid detergents for children (gels, shampoos, bath products, bath foam, liquid soap)

- Baby cream

- Face, hand, foot, body cream

Production capacities:

1. Equipment for the preparation of cosmetic mass (creams, gels, lotions, milk, scrubs, etc.)

2. Equipment for packaging cosmetic mass - 2 tubing lines (all types of creams):

- line for packing tubes with a diameter of 35 mm and a nominal capacity of 50-140 ml;

- line for packing tubes with a diameter of 25 mm, 35 mm, 50 mm and a nominal capacity of 14-250 ml.

3. Equipment for filling cosmetic mass in bottles and jars (all types of liquid detergents):

- 2 plants designed for filling low viscosity and high viscosity cosmetic masses with a nominal capacity from 50 to 500 ml;

- Doypack (500 ml, 1000 ml) and vials (150 ml, 240 ml, 300 ml, 500 ml, 1000 ml).

Disposable diapers and panties

Disposable diaper is a multi-layered product consisting of 5 main parts:

1. Anti-leaking barrier. It doesn’t allow moisture to flow out around the edges; prevents deformation.

2. Top sheet. Directly in contact with the baby skin (its task is to quickly absorb moisture and transfer it to the inner absorbent layer).

3. Distribution layer. Promotes uniform distribution of liquid over the surface and penetration into the center of the absorbent layer.

4. Absorbent layer of the diaper with SAP (superabsorbent). Provides dryness, instantly reacts, turning liquid into gel.

5. Outer layer, back sheet, is a non-woven fabric laminated with a polymer film, preventing the liquid from penetrating outwards.

Production facilities:

- Operating speed 400 pcs/min = 3,500,000 / pcs. per month = 80,000 packs per month.

- Easy to operate. More than 1,500 adjustable parameters and settings, with 400 - 500 of them constantly monitored during operation.

- Packing. A large number of packaging combinations.

- Product. Possibility to manufacture products of any class and size, by optimizing a selection of parameters for products with any characteristics.

Additional features:

- Elastic band on the back

- Hook-face band

Package:

- bags with handle

- bags without handle

Packing method: automated

Shelf life: 3 years

Diaper dimensions:

XS | MICRO | 2-5 kg |

S | MINI | 3-6 kg |

M | MIDI | 4-9 kg |

L | MAXI | 7-14 kg |

XL | JUNIOR | 11-25 kg |

Types of packages:

12-24 pcs | SMALL |

27-46 pcs | STANDART |

47-60 pcs | JUMBO |

61-98 pcs | MEGA |

> 99 pcs | GIGA |